Home / Hydro-mechanical cleaning of oil heating furnace coils

Hydro-mechanical cleaning of oil heating furnace coils

Coils of technological furnaces of oil refineries are one of the most loaded types of equipment.

During the operation of tubular furnaces, salts accumulate-stone, paraffin and coke deposits on the inner surface of the coil. These can be organic and inorganic substances. This leads to a decrease in heat transfer, a decrease in throughput, a reduction in the life of the coil, and an increase in flue gas consumption. These malicious processes lead to coil burnouts and emergency situations up to the ignition of the product.

To clean the inner surface of the coils of tubular furnaces, CTK-ASIA LLP uses the technology of hydromechanical cleaning that meets all the most modern requirements when performing such tasks.

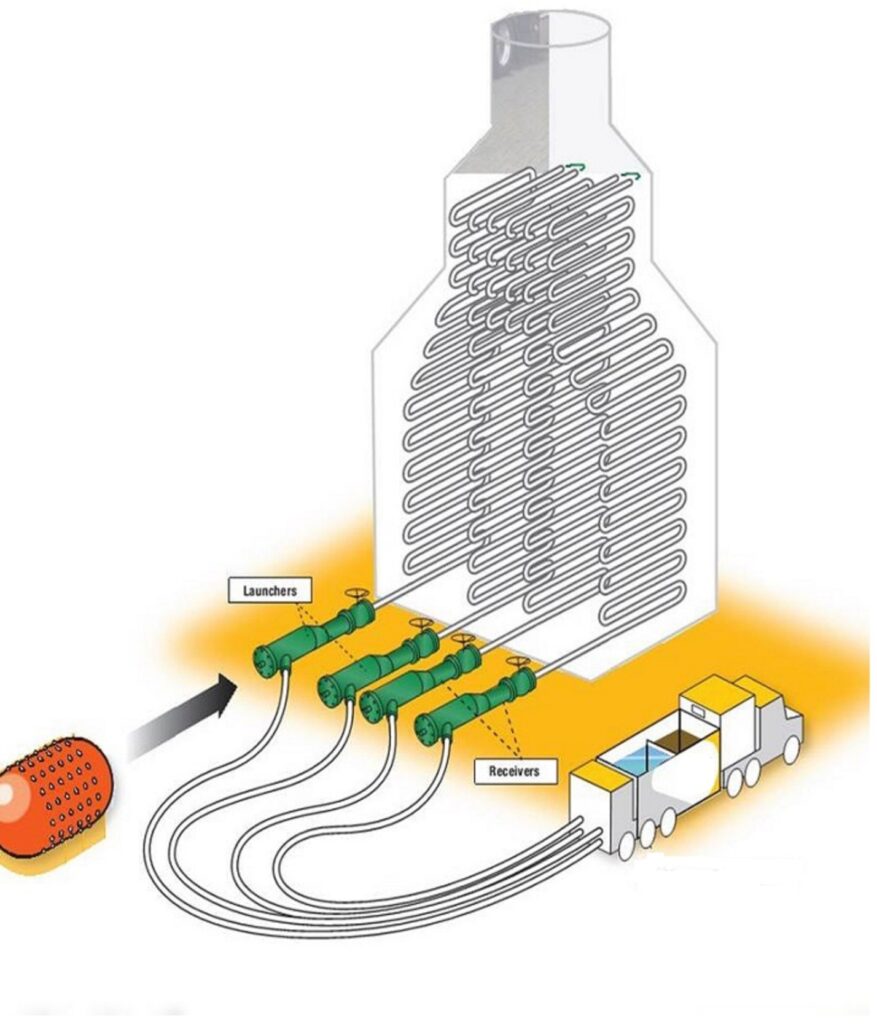

With the most modern equipment, as well as a wide range of cleaning shells, it is possible to clean various types of tubular fire furnaces operated at enterprises of the fuel and energy complex of the industry having in their design not only rectilinear sections of the furnace coil, but also steeply curved bends, as well as retrobend bends.

Using modern technologies in the field of hydro-mechanical cleaning and many years of experience in carrying out work, we guarantee the quality of the work performed.

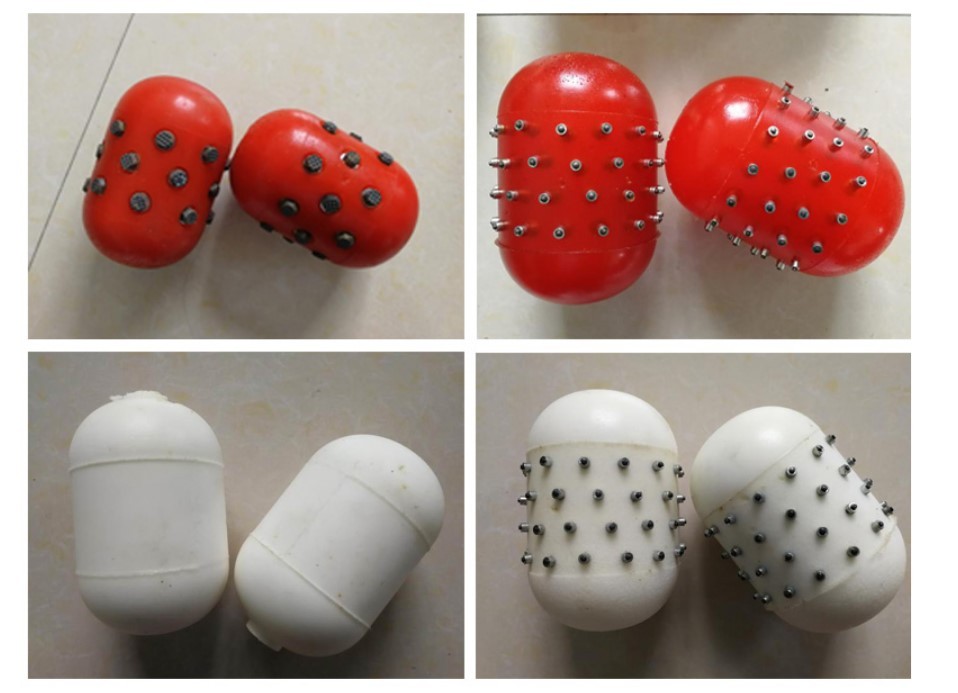

Various types of scrapers are used for hydro-mechanical cleaning of heating furnace coils and pipelines. The selection of the type of scrapers is carried out by a technical specialist depending on the cleaning object, the material of the coil pipes and the nature of deposits.

Cleaning shells (scrapers) are special products that are consumables for cleaning, made, as a rule, of polymer materials that allow cleaning the inner surface of the coils of fire furnaces and pipelines. Cleaning shells can have different shapes, sizes and structures (for example, have a soft or hard core), depending on the length and structure of the area being cleaned, as well as the amount and hardness of deposits, which allows them to pass not only steeply curved bends, but also returbends.

The outer surface of the scraper is covered with cleaning elements (spikes /bolts), their number and location may vary. The density of the material from which scrapers and cleaning elements are made can be selected within a wide range, which allows you to remove various types of dirt and deposits at the same time without causing any damage to the surface to be cleaned.

To assess the degree of contamination of the cleaned area and to assess the quality of its cleaning, soft test shells made of light polymer material are used.

Need a consultation?

Our specialists are always ready to advise you and answer any questions that arise. Call us by phone: +7 727 394 09 83 and get a consultation or fill out the form