Home / Chemical cleaning of process pipelines

Chemical cleaning of process pipelines

Among the pollutants that are most common in oil pipelines, it is worth mentioning paraffin deposits. They lead to a decrease in the flow section of the pipe and even to a complete blockage of the oil pipeline. Paraffin deposits occur due to the cooling of the transported oil, as well as due to its physico-chemical properties, pressure drops inherent in the pumping process, and the physical process of paraffin precipitation from petroleum products. In a normal situation, there is an uneven distribution of paraffin on the inner walls of the pipeline and its accumulation in the upper segment. This is due to the lower temperature of these sites. Paraffin deposits do not remain in the lower sections due to mechanical impurities, which literally strip off the dirt that gets in their way.

In order not to engage in forced premature cleaning, it is necessary to remember about the implementation of preventive measures that will maintain the capacity of oil pipelines. We are talking about such preventive measures as the annual cleaning of tanks from oil residues, which consists in: heat treatment of highly paraffinic types of oil (heating and cooling to a certain temperature), mixing of pumped types of oil and low-paraffinic or low-viscosity types, mechanical mixing or the introduction of special additives that increase oil fluidity.

Cleaning of the internal surfaces of the pipeline

The operation of oil pipelines is accompanied by the use of the following methods of cleaning their internal surfaces from deposits: thermal, chemical and mechanical. These methods can be used separately or in a complex. The essence of the thermal method of cleaning oil pipelines is to flush the pipeline with a coolant – hot petroleum products or steam with hot water. This method is used in those areas that differ in small diameter or small length of pipelines. The principle of the chemical cleaning method is to use some kind of cleaning solution. The most effective solutions are those that contain some part of the surfactants in the composition. We are talking about different classes of organic compounds with special physical and chemical properties. Even with a relatively small amount, they can lead to changes in the properties of surfaces and phase boundaries in the system containing them.

The principle of the action of detergents is their greater adsorption on the surface of dirt in comparison with dirt and paraffin particles, which leads to the displacement of the latter. To prevent problems associated with secondary deposition of particles separated from the surface on the pipe surfaces and their enlargement, high-molecular dispersants should be used. They contribute to the formation of protective polymolecular films surrounding the particles, ensuring their removal in the composition of the liquid.

Note the good efficiency of using cleaning solutions in situations where paraffin deposits are insignificant. With an increase in paraffin deposits, cleaning solutions have insufficient effect. In addition, cleaning solutions are effective only for removing paraffin from pipelines.

It is not possible to get rid of mechanical impurities (sand, clay, rust) and larger objects (stones, pieces of metal), which, remaining in the pipeline, lead to a decrease in its throughput.

The cleaning procedure using detergent reagents consists of:

- Stopping the operation process;

- Draining the product;

- Connecting pumps and creating closed circuits;

- Injection of solvent into the structure of the cleaned circuit;

- Circulation of the solution along the cleaning circuit;

- Draining of the reagent upon completion of cleaning.

It is not always possible to ensure 100% cleaning in a safe way if mechanical cleaning works are carried out in the pipeline.

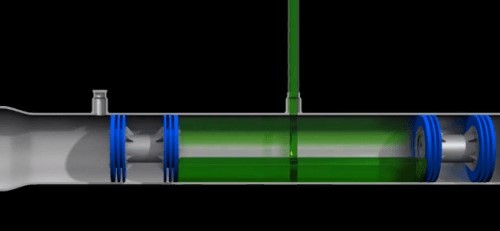

A more reliable way of chemical cleaning is considered to be cleaning by means of an artificially created plug in which the reagent is located.

The cleaning procedure consists of the following steps:

- Release of the pipeline from the product.

- Connection of a special plug with a reagent in it (this plug is shielded with the help of two in-pipe distribution pistons).

3. Movement of the plug along the cleaned contour, with simultaneous interaction of the reagent with deposits.

4. After passing a certain distance, the reagent is drained from the circuit.

5. At the next stage, an absorption plug is created from diesel fuel.

6. This traffic jam will have to go the same way to remove the last remnants of sediments, the same way goes, with the help of diesel fuel.

7. Diesel fuel is drained from the pipeline.

Thanks to this procedure, it is possible to achieve:

- Restoration of the maximum pipeline capacity;

- Safe repair or restoration of the pipeline without polluting the environment;

- Preservation of the pipeline for the required period, while excluding any corrosive effects;

- In the future, any environmental risks are excluded.

Need a consultation?

Our specialists are always ready to advise you and answer any questions that arise. Call us by phone: +7 727 394 09 83 and get a consultation or fill out the form