Home / Hydrodynamic tank cleaning

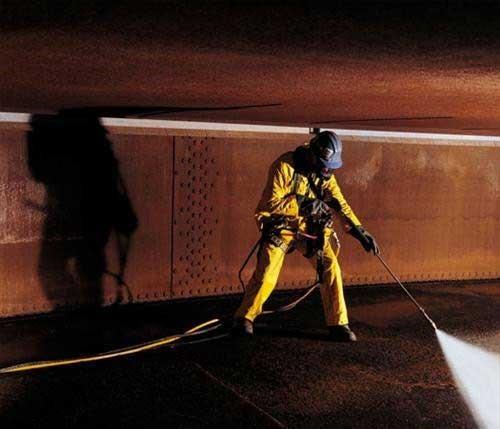

Hydrodynamic tank cleaning

Tank containers have proven to be the only acceptable for storing, collecting and transporting oil and products from it. It is durable and efficient, but all its qualities are lost over time due to improper maintenance. It is for this reason that, in order to avoid the wear of expensive equipment and the creation of emergency situations, the operating regulations prescribe regular cleaning of the container in which oil products were stored.

The order of stripping

The process of cleaning the tank from petroleum products involves processing:

The walls of the container in order to remove precipitation and rust. At the same time, standard rules do not require the performer to achieve 100% cleanliness of surfaces. At the end of the process, a small layer of sediment or rusty smudges may remain on the walls if their removal is difficult.

The bottom of the equipment. Bottom sediments cause more significant damage to the system. Therefore, maximum attention is paid to their cleaning. The same principles apply here as with the walls: after stripping, residues of impurities, precipitation or rust may remain on the surface, but within 0.1% of the total volume of the container.

The internal space of the equipment for the purpose of its degassing. At this stage, the remains of vapors released by petroleum products during their storage are removed. Here, the elimination of vapors may also be incomplete, but their concentration is measured and checked for compliance with acceptable values

Need a consultation?

Our specialists are always ready to advise you and answer any questions that arise. Call us by phone: +7 727 394 09 83 and get a consultation or fill out the form